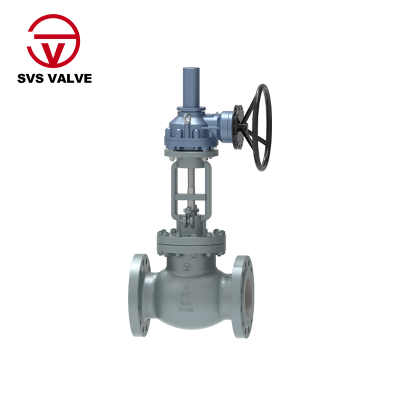

Our RF End Forged Steel Globe Valve is engineered for precise flow regulation and reliable shutoff in demanding industrial systems. Unlike other valves, its unique design with a plug-shaped disc and straight-line motion makes it perfect for applications where accurate throttling and fine-tuned control are critical. The robust forged steel body ensures exceptional durability and leak-free performance, even in the toughest conditions.

Built for Performance

This valve's unique globe design allows for a wide range of flow adjustments, giving you superior control over fluid rates. The straight-line motion of the disc and stem provides a short opening and closing time, minimizing wear and tear. A single, conical sealing face on both the body and disc ensures a reliable, tight shutoff, making it a dependable choice for isolation and regulation. With a rising stem design, you can also easily see the valve’s current status.

Ideal for Demanding Applications

The RF End Forged Steel Globe Valve is a trusted component across a variety of critical industries. Its robust construction and reliable performance make it a go-to solution for:

Oil and Gas: Handling high-pressure and high-temperature fluids.

Chemical Processing: Ensuring precise flow control of corrosive or hazardous chemicals.

Power Generation: Providing dependable shutoff and regulation in steam and water systems.

Petrochemicals: Maintaining fluid integrity and safety in refining and processing operations.

Design Features

- Exceptional Throttling: Our globe valve is designed for precise flow control, allowing for a wide range of adjustment.

- Secure Seal: The conical sealing surface and unique disc design ensure a tight, secure seal when the valve is fully closed.

- Durable Construction: Built with a forged steel body and a rising stem, this valve offers superior strength and a clear visual indicator of its open or closed status.

- Industry Standards: Manufactured and tested to meet or exceed key industry standards, including API 602 and API 598, ensuring reliable performance.

- Advanced Sealing: Features a back seat sealing structure and flexible graphite packing for enhanced security and leak prevention.

Product Specifications

Body Material: Stainless steel, forged steel, alloy steel

Nominal Diameter: 1/2" to 2 1/2"

Pressure Range: Class 150 to 2500 (PN10-PN420)

End Connection: RF (Raised Face)

Working Temperature: -29℃ to 560℃

Operation: Handwheel, Gear Box, Electric Actuator, etc.