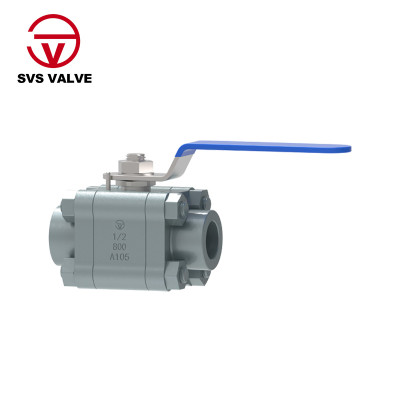

When failure is not an option, our High-Pressure Double Block and Bleed (DBB) Ball Valve provides the ultimate level of safety and sealing integrity. Engineered with a robust forged steel body and a sophisticated floating ball design, this valve is the definitive choice for the most critical, high-pressure applications.

How It Works: Uncompromising Double Seal

This valve's innovative design ensures a verifiable, zero-leakage seal by leveraging the system's own pressure.

- Dynamic Sealing: Under high-pressure conditions, the floating ball is dynamically pushed against both the upstream and downstream seats. This creates a redundant, bubble-tight double seal that stands up to the most demanding service.

- Verifiable Isolation: An integrated bleed port allows operators to safely vent the pressure between the two sealing rings. This crucial feature provides a verifiable indication of zero pressure, guaranteeing complete isolation before any maintenance or inspection.

Key Advantages

- Forged Steel Durability: The high-grade forged steel body provides exceptional strength and structural integrity, ensuring reliable performance and a long service life in harsh environments.

- Enhanced Safety: The DBB functionality is a critical safety feature, preventing the risk of fluid mixing and accidental pressure buildup, which is essential in hazardous operations.

- Simplified Installation: This single-valve solution replaces the complex, multi-valve setups traditionally used for isolation, reducing potential leak paths and simplifying your pipeline layout.

Ideal for Critical Applications

Our High-Pressure DBB Ball Valve is a trusted component in industries where fluid integrity and safety are paramount. It is the go-to solution for:

Oil & Gas: Providing secure isolation for upstream, midstream, and downstream operations.

Chemical Processing: Safely managing high-pressure and hazardous chemicals.

Power Generation: Ensuring reliable performance in steam and high-pressure fluid systems.